Gas Generators and Accessories

Efficient gassing

Our gassing devices can be used for all known gas-curing core production processes and are specially adapted to each process. A distinction is made between organic and inorganic processes.

In the organic process, the liquid medium is stored in a storage tank attached to the side and heated in an evaporator. This changes the aggregate state from liquid to gaseous and the medium can be fed into the core box for core hardening. The storage container can be filled both manually and automatically.

In the inorganic process, curing is carried out with hot air - compressed air is heated to correspondingly high temperatures in the heaters and fed into the core box for core curing.

It is also possible to combine different processes in a universal gassing device.

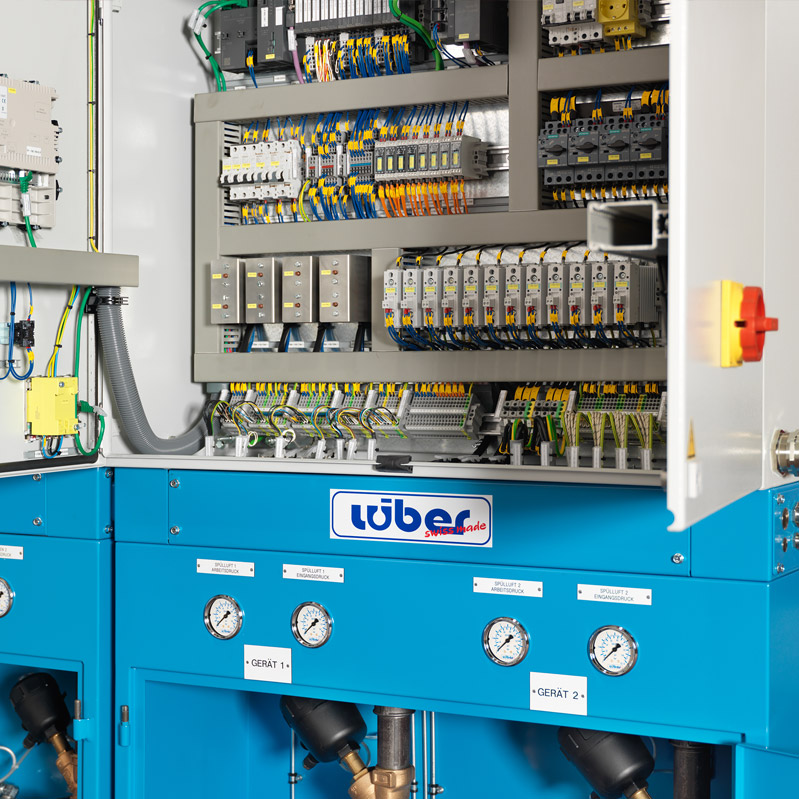

gas generator

Our gas generators offer:

- Optimum coordination of all components and good accessibility of all parts

- low energy and catalyst consumption

- Highest reproducible dosing accuracy thanks to precise control and electronic flow meters (patented)

- catalyst refilling without interrupting production

- maximum performance thanks to high-performance evaporator

- simple operation, high safety standard and low maintenance

- optional connection to our operating data acquisition system for the evaluation of all important data.

conformities:

Our gas generators are EC conformity and explosion protection compliant in accordance with directive 2014/39/EU and certified with the number SEV 08 ATEX 0114.

Central Amine Supply –

completely clean

pump station with storage tank

central amine supply

Our central amine supply (ZAV) is used to supply several gas generators with liquid media. The ZAV is equipped with an appropriately dimensioned storage tank, which enables filling via drums or containers. On demand, the media is supplied directly to the respective gas generators via a closed conduit system.

Safety

The central amine supply system complies with the ATEX directive and is equipped with several safety features. These include: the collecting tray under the storage tank and pump station with leak detection probe (tray in accordance with WHG § 19 I) and the leak detection test of the entire piping system. The medium is only pumped into the respective gas generators once the test has been passed and the corresponding release has been given.

Photo gallery