Mixing systems

Core sand mixing plants

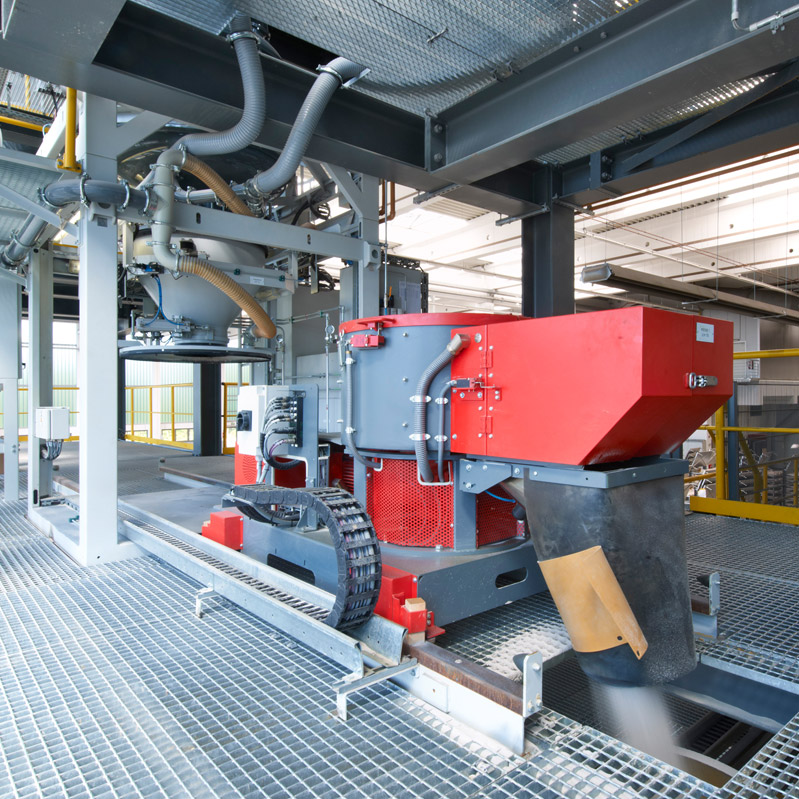

Our modular core sand mixing plants consist of individual components that are used to process core sand. The plant components are available both as individual assemblies - for example as a stand-alone mixer with its own control system - and as part of a fully automatic plant. Our core sand preparation systems can be used for almost all organic and inorganic core production processes used in core making. Our systems use different batch mixers - the universal batch mixer (UCM), the horizontal batch mixer (HCM) and the intensive core sand mixer (KIM, ball mixer).

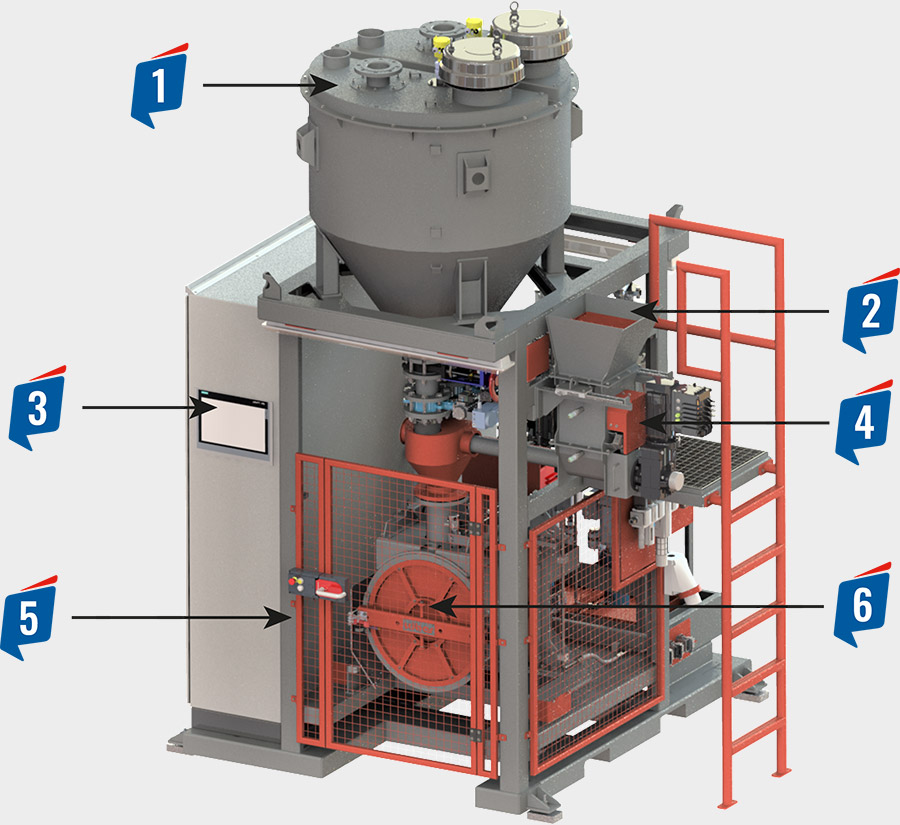

Legend

| 1 = sand silo | 2 = additive dosing | |

| 3 = sifter/fluidizer | 4 = balance | |

| 5 = plant frame | 6 = binder dosing and storage | |

| 7 = travelling mixer (UCM) |

| Technical data | UCM50 | UCM100 | UCM150 | UCM200 | UCM300 | UCM400 | UCM500 |

|---|---|---|---|---|---|---|---|

| max. batch size [kg] | 50 | 100 | 150 | 200 | 300 | 400 | 500 |

| min. batch size [kg] | 20 | 40 | 60 | 70 | 100 | 150 | 200 |

| mixing time [s] | 60-120 | ||||||

| capacity [kg/h] | 1500 | 3000 | 4500 | 6000 | 9000 | 12000 | 15000 |

Series LC with HCM

Our latest development in the field of core sand mixing plants is the LC compact mixing plant. It combines the advantages of our proven quality with high compactness and space-saving installation. This makes it particularly suitable for smaller foundries and installation sites with low headroom. The compact mixing system can be used for all common organic and inorganic production processes on the base of the proven binder dosing systems. The batch size is up to 70 kg with a maximum system capacity of 2 t/h.

Legend

| 1 = double chamber sand-silo | 2 = binder dosing and storage (back side) | |

| 3 = control cabinet | 4 = additive storage and dosing device (option) | |

| 5 = plant frame | 6 = Horizontal-Batch-Mixer (HCM) with load cells |

| technical data | HCM50 |

|---|---|

| max. batch size [kg] | 70 |

| min. batch size [kg] | 30 |

| mixing time [s] | 70-80 |

| capacity [kg/h] | 2250 |

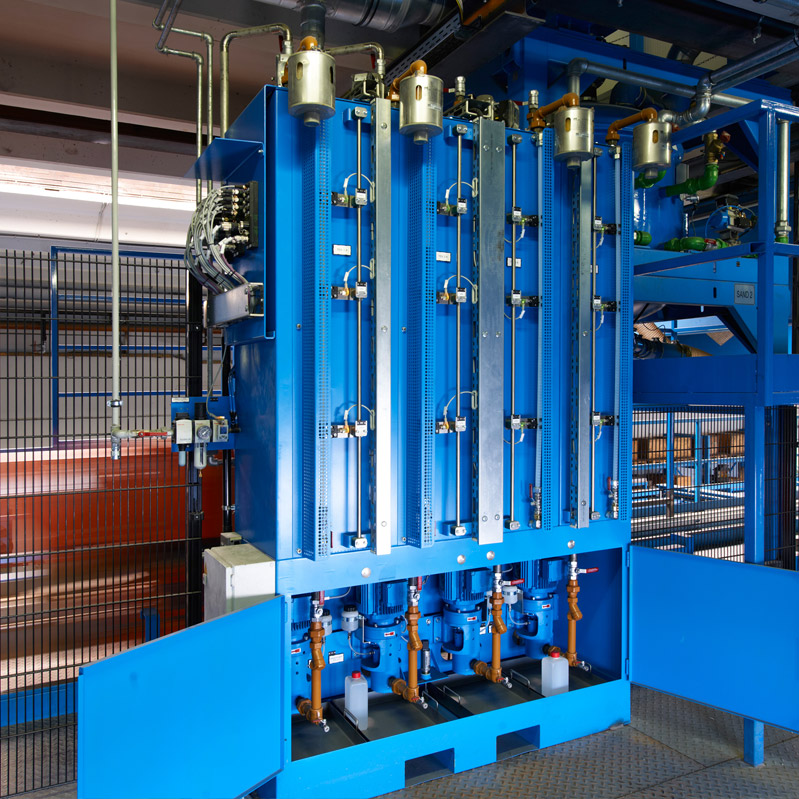

Binder storage and supply

We offer tank, container and drum storage facilities for the storage and transportation of binders in accordance with the German Water Resources Act. We offer tank storage facilities in various sizes for the acceptance of larger quantities of binder delivered by tanker. These can either be double-walled or fitted with a collecting tray. The binder is automatically transported to all recipients by means of appropriately dimensioned feed pumps.

Central sand storage and supply

We offer appropriate silo systems or "big bag" stations with feeder for the storage and pneumatic conveying of sands or powder additives. When delivering sand by tanker truck, we integrate the unloading and supply station to the mixing plant.

Video

Photo Gallery